Home > Products > Filtration Equipment & Parts > Hydraulic PP Chamber Plate Filter Press for Slurry Dewatering

Hydraulic PP Chamber Plate Filter Press for Slurry Dewatering

Hydraulic PP Chamber Plate Filter Press for Slurry Dewatering Introduction to Chamber Filter PressChamber Filter Press is the type of filter press that only use chamber filter plates, no diaphragm (membrane) squeeze plates. However, chamber plates are much cheaper than diaphragm plates, so init......

Send Inquiry

Product Description

Hydraulic PP Chamber Plate Filter Press for Slurry Dewatering

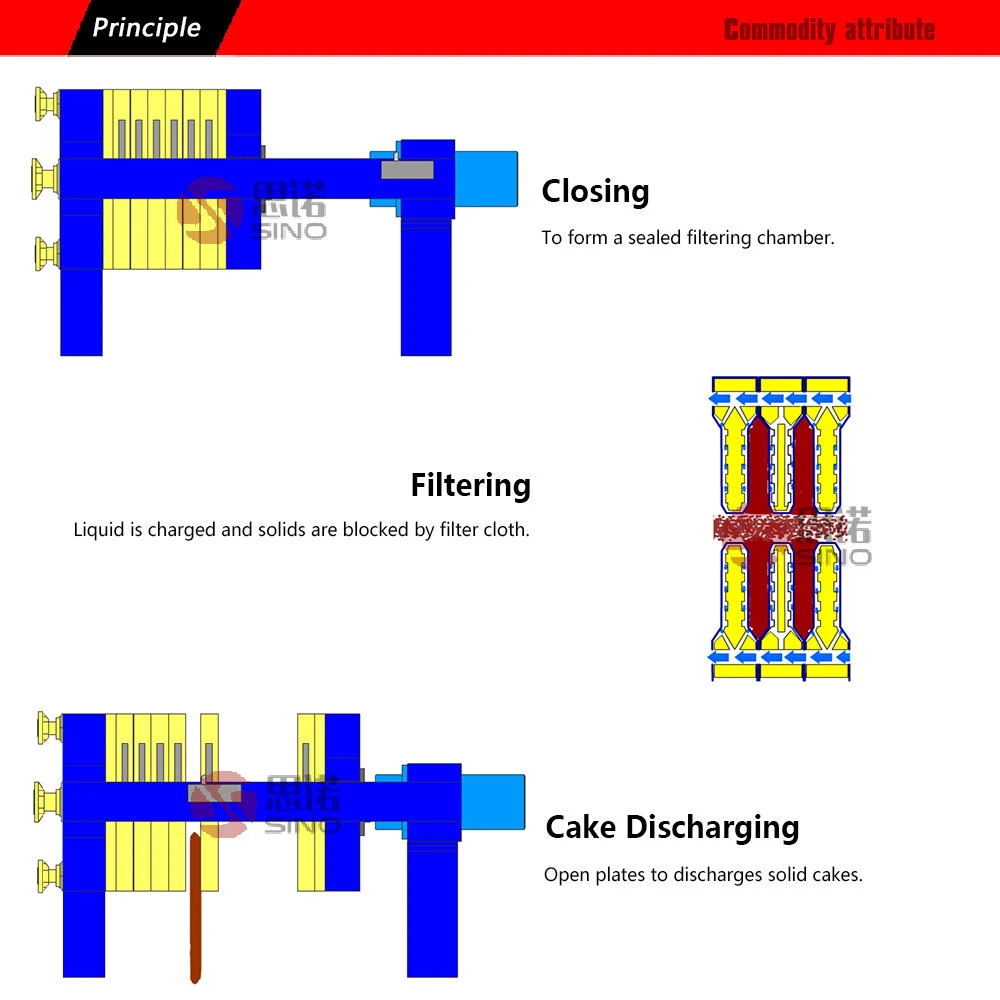

Introduction to Chamber Filter PressChamber Filter Press is the type of filter press that only use chamber filter plates, no diaphragm (membrane) squeeze plates. However, chamber plates are much cheaper than diaphragm plates, so initial investment and operation cost would be less. Meanwhile, we also developed a new type of high pressure chamber filter press, its filtration pressure can reach more than 1.2MPa. With this pressure, it can achieve similar results as diaphragm filter press.

Features of Chamber Filter Press Machine

1.Labor saving: Easy operation, one worker can supervise several machines' working.

2.Wide applications: For all kinds of solid-liquid separation.

3.Long lifetime: The beam is made by best carbon steel and not easy to out of shape, filter plate is made by high-quality PP material and can resist high temperature and high pressure.

4.Other additional devices also can be added such as filter cloth washing system, filtrate collecting system, filter cloth shaking system, drip tray system etc..

5.Feed pressure is high, can reach 1.5MPa.

6.High efficiency. Automatic cakes discharging.

7.It is used for large capacity, it can ensure good filtering effect.

8.It is steady in operation and easy in maintenance.

9.Chambers are filled with materials by center feeding.

Available Options According to:

Closing mode: manual, hydraulic, automatic.

Filter plate material: PP, cast iron, stainless steel;

Filter Plate size (mm) : 320, 450, 630, 800, 870, 1000, 1250, 1500, 2000

1. Chemical

Coating, paint, silica, caustic soda, etc..

2. Foods

Vegetable oil, sunflower oil, castor oil, linseed oil, etc..

3. Sewage

Printing and dyeing wastewater, sewage, smelting, leather, etc..

4. Pharmacy

Strain,Wells, calcium, Chinese traditional medicine, etc..

5. Pottery clay

Bentonite, glaze water, electronic ceramic soil, kaolin, etc..

6. Metallurgy

Gold, silver, copper, coal, zinc ore mineral powder, etc..

7. Petroleum

Diesel oil, used oil, shortening dewaxing etc..

After-sales Service & Technical Supports

1. Filter press installation, debugging.

Provide filter press installation files, technical data and related copies or videos etc..

2. Filter press warranty

Warranty: 12 months for the machine after delivery.

3. Filter press technical support

Our company will make occasional call to find problems and solve them in time.

Provide technical support timely.

4. 24 hours website hot line service.

For big filters order or project, dispatch technician is negotiable.

Specifications of Chamber Filter Press:

| Model | Filter Area (m2) | Volume (L) | Plate QTY (pcs) | Pressure (MPa) | Power (Kw) | Weight (Kg) | Dimensions (mm) |

| XMZ 30/870 | 30 | 460 | 23 | 0.6 | 2.2 | 2680 | 3180*1400*1230 |

| XMZ 40/870 | 40 | 595 | 30 | 3050 | 3570*1400*1230 | ||

| XMZ 50/870 | 50 | 748 | 38 | 3456 | 4110*1400*1230 | ||

| XMZ 60/870 | 60 | 902 | 46 | 4003 | 4550*1400*1230 | ||

| XMZ 70/870 | 70 | 1056 | 54 | 4584 | 4990*1400*1230 | ||

| XMZ 80/870 | 80 | 1210 | 62 | 5082 | 5430*1400*1230 | ||

| XMZ 50/1000 | 50 | 736 | 28 | 0.6 | 4 | 4128 | 4040*1500*1400 |

| XMZ 60/1000 | 60 | 889 | 34 | 4636 | 4460*1500*1400 | ||

| XMZ 70/1000 | 70 | 1041 | 40 | 5143 | 4760*1500*1400 | ||

| XMZ 80/1000 | 80 | 1193 | 46 | 5651 | 5120*1500*1400 | ||

| XMZ 100/1000 | 100 | 1475 | 57 | 6628 | 5780*1500*1400 | ||

| XMZ 120/1000 | 120 | 1777 | 69 | 7644 | 6500*1500*1400 | ||

| XMZ 100/1250 | 100 | 1468 | 36 | 0.6 | 4 | 8307 | 5020*1800*1600 |

| XMZ 120/1250 | 120 | 1746 | 43 | 9308 | 5470*1800*1600 | ||

| XMZ 140/1250 | 140 | 2063 | 51 | 10455 | 5990*1800*1600 | ||

| XMZ 160/1250 | 160 | 2341 | 58 | 11492 | 6450*1800*1600 | ||

| XMZ 180/1250 | 180 | 2619 | 65 | 12494 | 6905*1800*1600 | ||

| XMZ 200/1250 | 200 | 2896 | 72 | 13504 | 7360*1800*1600 | ||

| XMZ 220/1250 | 220 | 3214 | 80 | 14652 | 7880*1800*1600 | ||

| XMZ 250/1250 | 250 | 3650 | 91 | 16227 | 8600*1800*1600 | ||

| XMZ 200/1500 | 200 | 2998 | 49 | 0.6 | 11 | 20030 | 6400*2200*1900 |

| XMZ 250/1500 | 250 | 3594 | 61 | 22978 | 7225*2200*1900 | ||

| XMZ 300/1500 | 300 | 4347 | 74 | 26026 | 8130*2200*1900 | ||

| XMZ 350/1500 | 350 | 5043 | 86 | 29220 | 8950*2200*1900 | ||

| XMZ 400/1500 | 400 | 5796 | 99 | 32574 | 9880*2200*1900 | ||

| XMZ 450/1500 | 450 | 6492 | 111 | 35586 | 10690*2200*1900 | ||

| XMZ 500/1500 | 500 | 7187 | 123 | 38606 | 11560*2200*1900 | ||

| XMZ 500/2000 | 500 | 9686 | 69 | 0.6 | 15 | 34840 | 9965*2850*2400 |

| XMZ 600/2000 | 600 | 11900 | 85 | 38223 | 11155*2850*2400 | ||

| XMZ 700/2000 | 700 | 13838 | 99 | 41641 | 12345*2850*2400 | ||

| XMZ 800/2000 | 800 | 15775 | 113 | 45060 | 13535*2850*2400 | ||

| XMZ 900/2000 | 900 | 17851 | 128 | 48479 | 14725*2850*2400 | ||

| XMZ 1000/2000 | 1000 | 19788 | 142 | 51898 | 15915*2850*2400 |

Maintenance of Filter Press

The maintenance of filter press is very important, it must pay attention to the following aspects:

1.Carefully check at any moment whether all joints are reliable, and whether all components work well. If any abnormal situation is found, urgently inform the maintainers to check and repair.

2.Regularly check the sealing edges of filter plates to ensure the smoothness and cleanness before pressing.

3.Frequently wash the filter cloth and carefully check the filter cloth to ensure it without fold, damage and slag to keep it flat and in good condition, so as to guarantee the filtration performance.

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.